Ovens designed for double resin filling tretments of stone surfaces

When the stone for its significant defects , needs to be filled deeply , we recommend a double filling treatment .

The first fillig allows to cover partly of the marble imperfections, normally the most noticeable, that could even pass through the thickness of the stone.

The second filling applied to the same surface of the marble, allows to completely cover the holes and imperfections and compensates for any shrinkage of the first resin layer after its hardening, greatly improving the final result of the processing cycle .

After the polishing step , so you will succeed in obtaining a surface of excellent quality, even with marbles with noticeable problems of porosity and compactness .

The oven equipped with electronic ballasts with adjustable power, allows to adjust the amount of UV radiation depending on the speed of the transport. In this manner, it brings the first resin filling in a state of ” almost ” hardening ( so called gelification ) , allowing the resin of the second application adhere perfectly to the underlying layer .

The stone, after the second grouting , will pass through a second oven for the total UV curing.

Ask for information

Our experts will help you find the solution that best suits you.

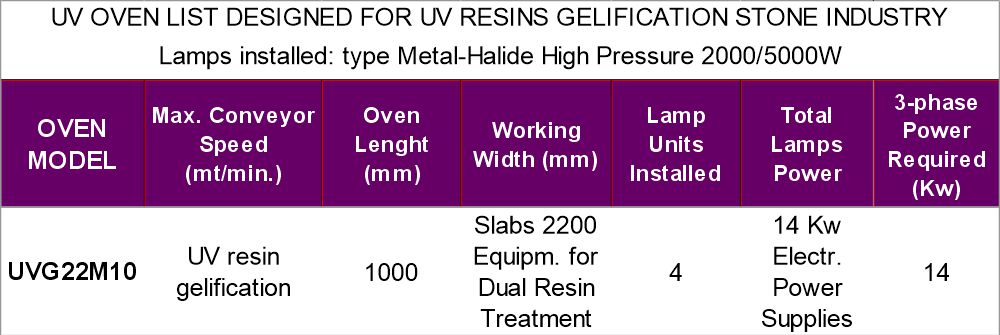

Tecnical specifications

-

High power Metal-Halide lamps (3500W)

-

Lamps with 3 types of radiation available, for a perfect UV resins curing

-

Equipped with electronic power supplies with adjustable power

-

The adjustable UV power allows you to give the right degree of gelling of the single-component resin applied, also in relation to the speed of movement of the roller conveyor.

Fields of application

-

Marble slabs and tiles surface treatment for filling imperfections by UV single component resins

-

Gelling of the first layer of resin in double filling treatments of slabs and tiles.